GRIDEX G

|

PRESENTATION |

|

____________ GRIDS PREPARATION ____________ After being cut out, the consecutive bands of a grid are alternatively separated and insulated from each other by an internal separator consisting of a box or stainless steel flanked by two sheets of mica.

|

|

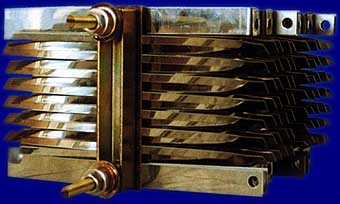

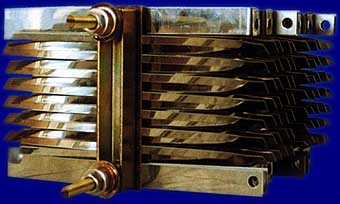

____________ GRIDS ASSEMBLY ____________ The grids with their internal separator are screwed on two tie-rods and insulated from each other by external separators, themselves attached to two mica sheets. The tie-rods are insulated by a mica grommet. The stacking thus obtained, after treatment in a steam bath, is press-clamped to form a compact battery.

|

|

____________ GRIDES CONNECTION ____________ Continuity of the electrical circuit is obtained by spotwelding the end bands of the consecutive grids. The junctions are designed to act as taps, to which it is possible to connect screw and nut. Finally, the ends band are twisted, to prevent any possibility of contact between them. The Gridex G, thus assembled, makes a sturdy, stainless steel unit which is maintenance free and easy to connect. |

|

|

APPLICATION |

| Rheostatic control starting resistors for slip ring motor or squirel cage motor |

|

ALLIAGES |

| The different type of used alloys are : |

|

Ferritic steel AISI 304- 18/10 Stainless Steel - Refractory Steel - Cupro Nickel Alloy - Aluchrome |